The overview of current and planned internal logistical processes is one of the challenges of standard Microsoft Dynamics 365 for Finance and Operations .

Advanced Warehouse Management provides valuable insights:

Warehouse management > Setup > Warehouse activity > Forecast > Warehouse activity week plan

Most warehouses are organized in a weekly recurring scheme, with typical activities on week days and time blocks per week day.

E.g. the picking activity for carrier Post is between 11:30 and 14:00, and the carrier is loaded between 14:30 and 15:00, but on Fridays picking and loading starts 1 hour earlier.

To be able to forecast the activity in the warehouse, the historical data can be used, and for the upcoming days or even hours, it will be more reliable to extrapolate the open lines.

Create a planned inbound or outbound activity that occurs every week. The activities can be inbound-related, outbound related or internal.

The planned pick start, pick end, loading start, loading end, and ship time can be entered and compared with the actual times shown in the warehouse activity forecast and actuals.

All times are in the time zone of the site.

| Field | Description | Remark |

| Warehouse |

|

Weekdays |

Day of the week |

|

|

Mode of delivery |

Mode of delivery or Carrier and service |

|

|

Direction |

None for internal activities like counting, stock movements | |

|

Work order type |

Sales orders, Purchase orders etc. |

|

|

Description |

||

|

Pick start |

Planned start time of picking activity |

Can be compared with actual start time |

|

Pick end |

Planned end time of picking |

Can be compared with actual end time |

|

Loading start |

Planned start time of loading |

Can be compared with actual start time or dock appointment check in time |

|

Loading end |

Planned end time of loading |

Can be compared with actual end time |

|

Ship time |

Planned ship time or cut off time |

Can be compared with the shipment confirmation times or dock appointment check out time |

Button Order entry pattern for forecast

E.g. 1 day before the ship date at 8:00, 40% of the order lines are entered in the system. 0 days before the ship date at 13:00, 90% of the order lines is in the system.

| Field | Description | Remark |

| Days before ship date | If the forecast for shipment lines to be shipped on Wednesday is generated on Tuesday, days before ship date is 1 |

Determine the average order lead times for this mode of delivery and the typical distribution of order entry in the days prior to shipping. Create multiple lines for different days and times to calculate a precise extrapolation. |

|

Weekdays |

Determined automatically based on activity weekday minus the number of days before shipdate |

If activity is on Wednesday and Days before ship date is 1, the cumulative percentage of order lines is entered by this time on Tuesday. |

|

Time |

Time of day for this site |

|

|

Order entry (cumulative %) |

Cumulative % of order lines in the system, n days before ship date at this time |

If 40 % is in the system 1 day before, the forecasted number of lines is 2.5 x the open lines. |

Button Weighted Moving Average

| Field | Description | Remark |

| Days before ship date | If the forecast for shipment lines to be shipped on Wednesday is generated and there are no or no significat number of open lines in the system, use the weighted average of historical data |

E.g. 7 days before shipment: 40% 14 days before shipment: 30% 21 days before shipment 20% 28 days before shipment 10% |

|

Percent |

Weighted moving average percentage |

Purpose

Provide an overview of warehouse work load for the coming days, weeks based on open orders before they are released to the warehouse.

Compare with historical data on the same week number, week day, to forecast the expected work load even before the orders are in the system.

Display the historical and predicted inbound and outbound number of pallets, cases, etc.

Estimated hours per load does the break down per load (e.g. an individual truck or a shipping container that must be unloaded or loaded on a specific date.

Warehouse management > Inquiries and reports > Warehouse activity > Warehouse activity forecast and actuals

The data in this form is calculated through a batch job which typically runs every night.

Actual

The actual in- and outbound shipments and lines per day are based on the date for which the shipment was confirmed, and the load lines for these shipments.

Open

The open inbound shipments and lines per day are based on the confirmed receipt date on the open purchase order lines.

The open outbound shipments and lines per day are based on the confirmed shipping date (or the requested shipping date) of the sales order lines and shipping dates of transfer order lines.

Forecast

The forecasted shipments and lines per day are based on extrapolated open lines for the upcoming n days, and a weighted moving average of the historical lines after n days from now.

| Field | Description | Remark |

| Date |

Expected date Actual date |

Expected physical date Physical shipment confirmation date |

|

Year |

||

|

Week |

||

|

Weekday |

||

|

Warehouse |

||

|

Mode of delivery |

Mode of delivery (carrier + service) |

|

|

Direction |

Inbound or outbound |

|

Work order type |

Purchase, sales, transfer |

|

|

Type |

||

|

Lines |

Number of shipment lines |

|

|

Shipments |

Number of shipments |

|

|

Hours estim. |

centi-hours | |

|

Hours actual |

Actual lines: actual duration of work lines |

centi-hours |

|

Pallets |

Closed works + closed packed containers, with transport unit type Pallet, or expected number of pallets |

|

|

Cases |

Closed cases works + closed packed cases, with transport unit type Case, or expected number of cases |

|

|

Misc. |

Closed miscellaneous works + closed packed miscellaneous units, with transport unit type Misc., or expected number of miscellaneous untits |

|

|

Pick start |

First pick start time for any shipment on this date, warehouse and mode of delivery |

|

|

Pick end |

Last pick end time for any shipments on this date, warehouse and mode of delivery |

|

|

Loading start |

First put time to final shipping location on this date, warehouse and mode of delivery |

|

Loading end |

Last put time to final shipping location on this date, warehouse and mode of delivery |

|

Transportation method |

Transportation method of the carrier + service |

E.g. Truck, e-truck, express delivery |

|

Shipping carrier |

Carrier |

Column can be inserted in the grid |

|

Carrier service |

Service |

Column can be inserted in the grid |

|

Volume (calculated) |

Column can be inserted in the grid |

|

Weight (calculated) |

Column can be inserted in the grid |

*) switch on Show quantity details to discern between containers from the packing station and work to the baydoor

Button Transactions displays the actual shipments or the open orders.

Button Recalculate will calculate the totals of the current line again (open orders only).

The number of pallets, cases and miscellaneous units calculated in a similar way per dock appointment and displayed in the Dock appointment scheduler when an appointment is opened.

When migrating from a legacy system, historical data can be uploaded to this table.

Warehouse management > Inquiries and reports > Warehouse activity forecast > Estimated hours per load

The data in this form is calculated through a batch job which typically runs every night or on request.

| Field | Description | Remark |

| Load ID |

|

Direction |

Inbound or outbound |

|

|

ETA |

Estimated date / time of arrival |

|

|

Scheduled load shipping date |

Planned date / time, inherited from dock appointment |

|

|

Warehouse |

||

|

Shipping carrier |

||

|

Carrier service |

|

Pallets |

Estimated number of pallets |

Based on logistics standard data per item |

|

Cases |

Estimated number of cases |

Based on logistics standard data per item |

|

Misc. |

Estimated number of miscellaneous units |

Based on logistics standard data per item |

|

Hours estim. |

Estimated number of man hours for this load |

Based on logistics data per (item and) warehouse (centi-hours) |

Warehouse management > Periodic tasks > Warehouse activity forecast > Generate logistics standard data

The quantity per case and the quantity per pallet are defined in the unit conversions. This data is used in the calulation of estimated hours per load and warehouse activity forecast.

This calculation can run in batch, typically after new items are added.

Warehouse management > Periodic tasks > Warehouse activity forecast > Warehouse activity forecast calculation

Calculates the aggregated number of lines (expected and historical) and other data per warehouse, carrier, date. Select Process open lines with or without generate forecast and/or Process actuals.

Select a period and a warehouse, or (re-)process a specific date.

This calculation can run in batch, one or few times per day.

Warehouse management > Periodic tasks > Warehouse activity forecast > Calculate estimated hours per load

Calculates the detailed estimated hours for open inbound or outbound loads, even before work is created and labor standards are applied.

Select a warehouse, and optionally filter.

This calculation can run in batch, one or more times per day.

Warehouse management > Setup > Containers > Container types

The typical transport unit type for containers can be specified on the container type.

| Field | Description | Remark |

| Transport unit type |

[Empty] Miscellaneous Pallet Case |

Should this container count as a pallet or case or misc. unit in the Warehouse activity actuals? |

Warehouse management > Setup > Work > Work templates

The typical transport unit type for work heading to the final shipping location can be specified on the work template.

| Field | Description | Remark |

| Transport unit type |

[Empty] Miscellaneous Pallet Case |

Should this work count as a pallet or case or misc. unit in the Warehouse activity actuals? |

Warehouse management > Setup > Warehouse activity > Default units per transport type

The warehouse activity forecast aggregates multiple units to three main categories: Pallet, Case, Miscellaneous. Miscellaneous can be used for specific logistic planning units like 6m length bundle, roll container etc.

| Field | Description | Remark |

| Transport unit type |

Miscellaneous Pallet Case |

Aggregated category for this unit |

|

Unit |

Unit that refers to a case or pallet |

|

Priority |

If conversions to multiple units are specified for the same item |

E.g. for the same item, there can be a conversion from Euro pallets and from Block pallets. Prio 1 prevails |

Warehouse management > Setup > Warehouse activity > Logistics standard data per item

In this form, the standard pallet quantity, and/or standard case quantity is maintained per item.

If the item has a different transport unit type that does not resemble a pallet or a case (e.g. 4 m roll), specify the unity for this miscellaneous unit.

Note this data serves a simple aggregation of inventory units to number of pallets. The unit sequence group and unit conversion is not used for this purpose. Not all companies use multiple units in the unit sequence groups.

| Field | Description | Remark |

| Item number |

|

Standard pallet quantity |

Number of inventory units on one pallet |

If the item is received or shipped in different pallet types (e.g. Euro and Block), enter the quantity for the most used pallet type |

|

Standard case quantity |

Number of inventory units in one case |

If the item is received or shipped in different case types, enter the quantity for the most used case type |

|

Standard quantity (misc.) |

Number of inventory units in one transport unit of type miscellaneous |

This data can be uploaded through the data entity / open in Excel.

Warehouse management > Setup > Warehouse activity > Logistics standard data per item and warehouse

In this form, the standard number of pallets, cases, misc. per hour (inbound, resp. outbound) is maintained per item and warehouse.

| Field | Description | Remark |

| Item number |

|

Warehouse |

|

Pallets per hour (inbound) |

Average (or median) number of inbound pallets handling per resource per hour |

|

|

Cases per hour (inbound) |

Average (or median) number of inbound cases handling per resource per hour |

|

|

Misc. per hour (inbound) |

Average (or median) number of inbound miscellaneous units handling per resource per hour |

|

|

Pallets per hour (outbound) |

Average (or median) number of outbound pallets handling per resource per hour |

|

|

Cases per hour (outbound) |

Average (or median) number of outbound cases handling per resource per hour |

|

|

Misc. per hour (outbound) |

Average (or median) number of outbound miscellaneous units handling per resource per hour |

This data can be uploaded through the data entity / open in Excel.

Warehouse management > Periodic tasks > Warehouse activity > Generate logistics item summary

In the dialog, select the warehouse and the days back to summarize the actual work lines per item and work line type.

This process can run in batch, e.g. every week over the past 60 days. It helps to identify the typical problematic items per warehouse.

Warehouse management > Inquiries and reports > Warehouse activity > Logistics item summary

This table contains the summarized data, which can be used for top 10 most picked items, etc.

| Field | Description | Remark |

| Item number |

|

Product name |

||

|

Warehouse |

||

|

Receipts |

The number of work lines that is received from purchase or transfer or production to a non staging location |

|

|

Replenishment |

The number of work lines taht are replenished to a non staging location |

|

|

Picks |

The number of pick lines for sales, transfer issue and raw material |

|

|

Cross docks |

The number of cross dock lines for sales and transfer |

|

Returns |

The number of returns (RMAs) that are received and put to a non staging location |

|

|

Receipt exceptions |

The number of exceptions registered during purchase receipt |

|

|

Short picks |

The number of short pick exceptions during picking |

|

|

Received |

Received quantity in inventory units from a purchase order, transfer order, production order that are put to a non staging location |

|

|

Picked |

Picked quantity in inventory units for sales lines, transfer issue or raw material picking |

|

|

Counting differences |

The number of accepted and posted counting differences |

|

Adjustments |

The number of posted stock adjustments (+ and -) |

|

Customers |

The number of distinct customers that are served by this item |

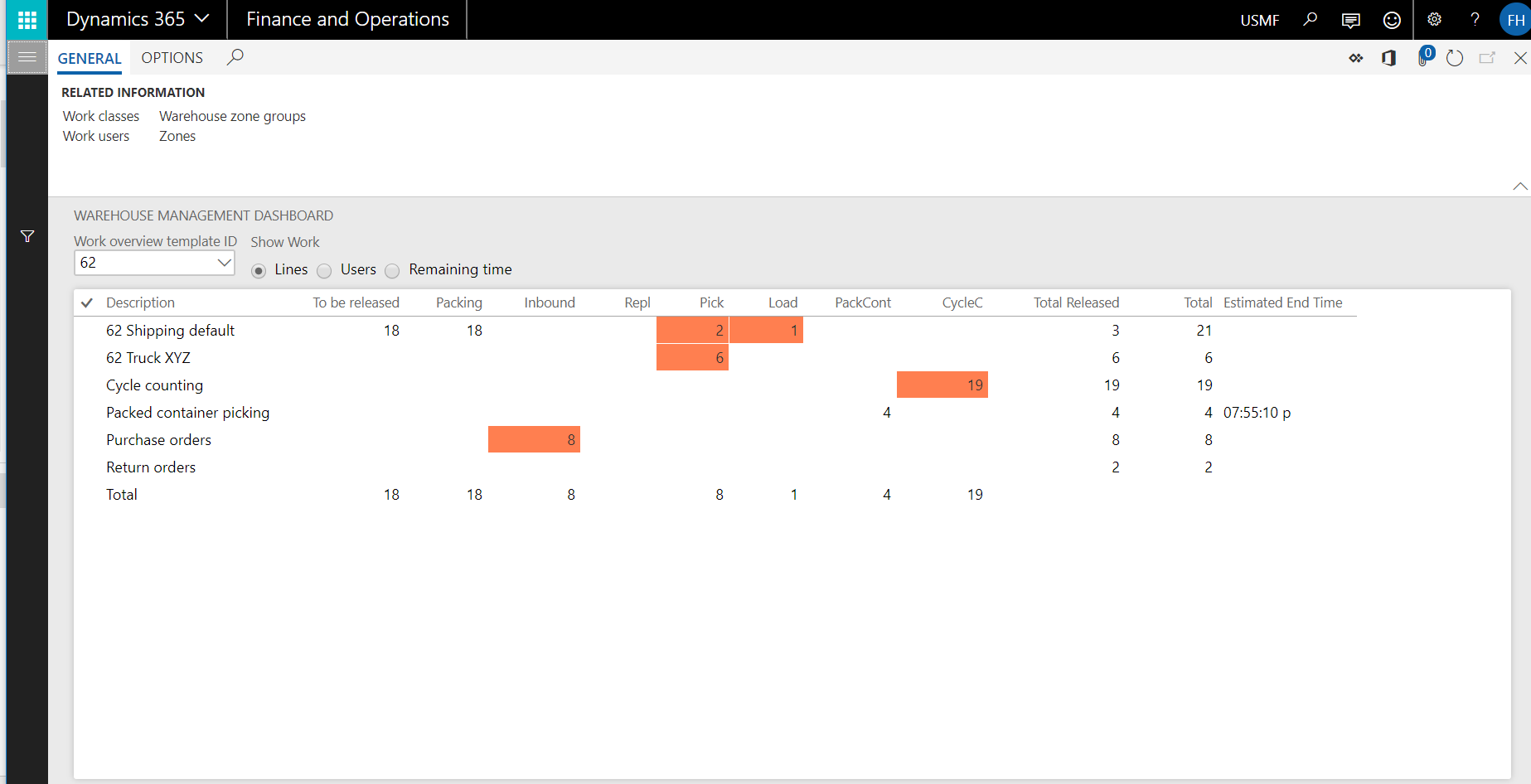

Warehouse management > Inquiries and reports > Dashboard

“Logistics is all about prioritizing”.

The Advanced Warehouse Management dashboard gives an immediate answer to day-to-day questions like:

The warehouse dashboard shows:

The dashboard distinguishes between:

Prerequisite for the remaining estimated time:

The remaining estimated time and estimated end time is always indicative.

Assumption before the wave is processed:

Assumption after the wave is processed and the work created:

The auto refresh interval larger than zero can be set in the Warehouse management parameters, General, group Work, Dashboard refresh time (minutes). This is useful if the dashboard is displayed on a large overview screen which is mounted on the wall.

From the dashboard, multiple overviews can be opened:

Note that the overviews show all data, and the user can filter manually.

The dashboard shows the number of wave lines that are not processed yet. The user can define up to twenty additional columns, and each of these columns can represent the amount of open work within one or more work classes and warehouses. E.g. define a separate column for the open narrow aisle truck work, or counting work in a specific part of the warehouse.

In case no worker is involved in the work defined in a specific task which must be executed, this dashboard cell gets an orange color.

If one or more workers are executing the work defined in a specific task, the estimated end time of the work is displayed in the dashboard.

| Field | Description | Remark |

| Description | Wave template name | Type of work, e.g. Purchase, Cycle count, Replenish |

|

To be released |

Non processed wave lines |

- |

|

Packing |

Open lines for packing station |

- |

|

User defined column 1..20 |

Open lines according to the dashboard template setup |

Open lines according to the dashboard template setup |

|

Total released |

Open work lines |

Open work lines |

|

Total |

Non processed wave lines + open work lines |

Open work lines |

|

Estimated end time |

- |

Warehouse management > Outbound waves > Shipment waves > All waves > Button: Update dashboard filter

Each wave template is displayed on a separate line in the dashboard. If you want to split these lines, it is possible to set different wave template filter codes on different waves. This is useful if each wave should be finished at a certain time slot, and a different wave with the same wave template name has a different time slot.

The update dashboard filter form displays the total number of shipments (wave lines), the total number of load lines, the percentage complete, the volume and the estimated remaining work hours to complete this wave.

Warehouse management > Inquiries and reports > Zone overview > Work classes

| Field | Description | Remark |

| Work class ID | Identification of the work class | Work class typically discerns between: • Work order type (sales, replenish etc.) • Warehouse area • Required fork lift type • Height of the location • Required skill level of the worker • Mobile device menu authorization |

|

Description |

Description of the work class |

|

|

Work order type |

Type of work |

E.g. sales, purchase, replenishment, production |

|

Open lines |

Number of open lines |

Both pick and put type |

|

Hours |

Remaining (decimal) hours |

Based on labor standards |

|

Name |

Mobile device user(s) |

Worker(s) executing work in this class |

Labor standards should be set up to display estimated remaining hours.

No further setup required.

Warehouse management > Inquiries and reports > Zone overview > Work users

| Field | Description | Remark |

| Status | Mobile device user activity status, similar to the Skype for Business indicator, referring to last activity. | Green Active Yellow 3-10 minutes inactive Orange 10-30 minutes inactive Red 30+ minutes inactive Grey 1 or more days inactive White Not logged in Red X User disabled |

|

User ID |

Mobile device login ID of the worker |

|

|

User name |

Name of worker |

|

|

Default warehouse |

Default warehouse of worker |

|

|

Work class ID |

Worker is currently executing work in this work class |

|

|

Zone ID |

Worker is currently active in this zone |

|

|

Location |

Worker is heading for / currently active on this location |

|

Destination |

Current work will be finished at this destination location |

|

Estimated time |

Expected time of arrival at destination location |

Based on estimated remaining time for current work, calculated by labor standards |

Labor standards should be set up to see the estimated time of arrival.

No further setup required.

Warehouse management > Inquiries and reports > Zone overview > Warehouse zone groups

| Field | Description | Remark |

| Zone group ID | Zone group | E.g. a hall in the warehouse |

|

Zone group name |

Name |

|

|

Estimated hours |

Estimated hours for non-processed waves |

Based on average number of transactions, and the estimated zone group upon creation of the wave line |

|

Open lines |

Number of open work lines |

|

|

Purchase |

Number of open work lines |

|

|

Replenishment |

Number of open work lines |

|

|

Transfer issue |

Number of open work lines |

|

Sales |

Number of open work lines |

|

|

Cycle counting |

Number of locations that require cycle counting |

If cycle count work is created per product: number of products and locations for which open cycle counting work lines exists |

|

Other |

Number of other open work lines |

E.g. raw material pick, production put away |

|

Hours |

Remaining hours |

Based on labor standards |

|

Name |

Mobile device user(s) currently working in / heading for this zone group |

Labor standards should be set up to display estimated remaining hours.

No further setup required.

Warehouse management > Inquiries and reports > Zone overview > Work classes

| Field | Description | Remark |

| Zone ID | Zone (group of locations) |

|

Zone name |

Name |

|

|

Zone group ID |

Group of zones |

|

|

Open lines |

Total open work lines |

|

Hours |

Remaining hours |

Based on labor standards |

|

Name |

Mobile device user(s) |

Workers currently working in this zone |

Labor standards should be set up to display the estimated remaining hours.

No further setup required.